Use of Six Sigma in a Call Center

Six sigma is a widely used technique to improve the customer experience in every industry. Though first introduced by Motorola in 1987 this technique is now being embraced by every industry.

In the last few years, the call center industry has also used Six Sigma technology to improve customer service.

|

| What is the use of Six Sigma in a Call Center |

With the increasing trend of Six Sigma technology in the call center industry, now call centers have also started giving priority to the selection of candidates for the manager or leadership profile who is Six Sigma certified, especially when it comes to the training and quality leadership roles.

Without further ado let's start today's topic i.e.

"What is the use of Six Sigma in the call center?"

But before plunging into the main topic let me first give you a brief introduction to the Six Sigma methodology

What is the Six Sigma technique?

The six Sigma process can be defined as a "methodology or a tool that is used to improve customer satisfaction by reducing the errors to near zero".

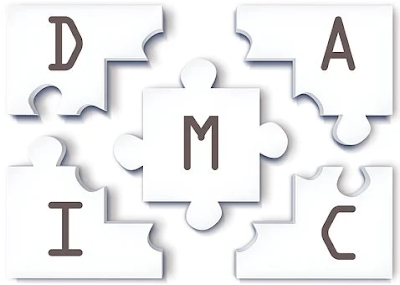

The six sigma methodology goes through 5 phases which are (in short) known as DMAIC.

Below is the step-wise pictorial representation of the process.

To become a six sigma consultant you need to complete a thorough course of six sigma which includes:

1. While Belt Certification.

2. Yellow Belt Certification.

3. Green Belt Certification.

4. Black Belt Certification.

5. Master Black Belt Certification.

Use of Six Sigma in Call Center:

The use of the Six Sigma methodology is in vogue in the call center industry. There can be many use cases of Six Sigma in a call center but a few of the common use cases are Reducing AHT, Improving NPS/ CSAT, Attrition Control, or Hiring delay

We will look into one common case i.e AHT reduction to understand how the Six Sigma methodology works in the call center.

Object : Reducing AHT

Let's understand it by an example.

A call center (XYZ) is handling an e-commerce project but in the last 3-4 months due to the no improvement in advisors AHT, C-SAT is significantly dropped and the credibility of the project is at stake.

The call center hired one six sigma consultant (Tony) to reduce the AHT.

Improve phase is primarily to figure out various problem solutions for the identified root cause of a problem ( high AHT in our case) which can be implemented further to get the desired result.

There are several statistical tests and tools to conclude the best possible solution for the identified problem.

5. C-Control:

Control is the last phase of the Six Sigma methodology. In this phase we observe and validate the improvement.As the name defines the primary role in this phase is to control the improvement validated.

Further in this phase, we prepare a flow chart on how to maintain control.

By following the above 5 phases a call center can see a decreasing trend of AHT (Average Handling Time).

However one needs to understand that the six sigma methodology is a time taking process and can take up to 6 months to show significationt improvement.

This is why most of the call centers do not apply it till the time they agreed on the aforesaid time period to expect the result.

1 Comments

I've also kept observe of what machines the other top 3D precision machining printing reviewers are impressed with, and included a few of them in my record as properly. ZDNET's suggestions are primarily based on many hours of testing, research, and comparability buying. We gather information from the best available sources, including vendor and retailer listings {as properly as|in addition to} different relevant and unbiased reviews sites.

ReplyDelete